what are the three basic areas of a machine that require safeguarding

The point of operation the power transmission device and the operating controls. That point where work is performed on the.

Machine Guarding Different Types Of Machine Guards

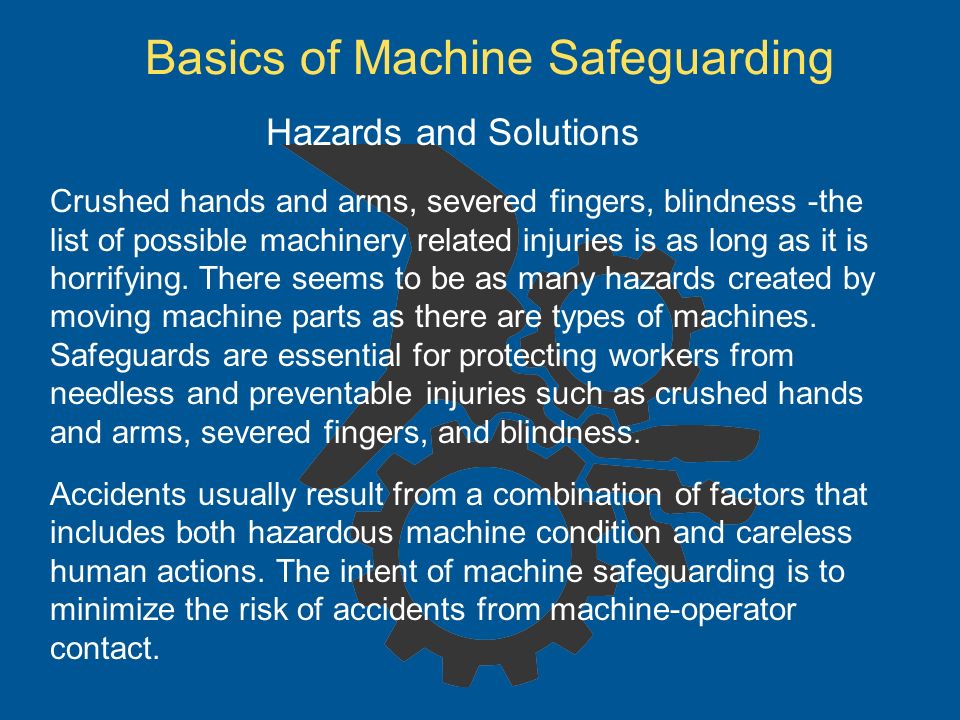

Dangerous moving parts in three basic areas require safeguarding.

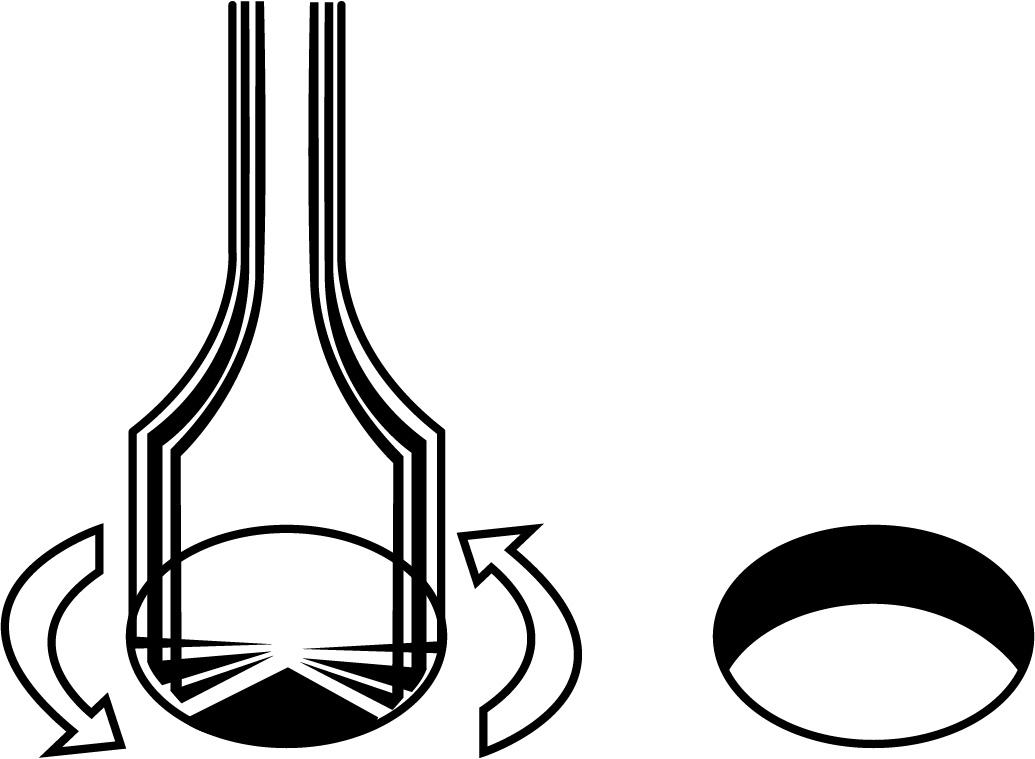

. The point of operation. Dangerous moving parts in three basic areas require safeguarding. The point of operation.

Point-of-operation safeguarding is usually designed with two primary objectives. The point of operation from where all the work is performed. Prevent human access during hazardous machine motion.

Guards are barriers which prevent access to danger areas. The moving parts on a machine do not constitute a potential machine guarding hazard. What are the three basic areas of a machine that require safeguarding.

The point of operation. What are the three basic areas of a machine that require. The point of operation.

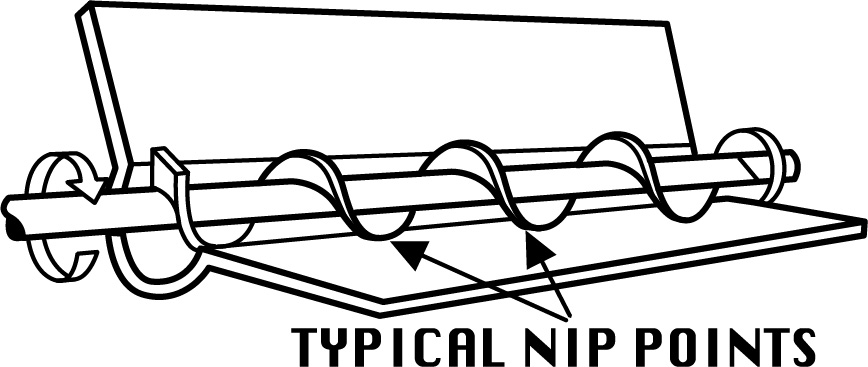

Mechanical hazards typically involve dangerous moving parts in the following three basic areas. The point of operation. Machine Guarding Introduction.

OSHA states that mechanical hazards are most likely to occur in three major areas. The point of operation that point where work is. Point of Operation Power Transmission Apparatus Other Moving Parts Question 2.

Dangerous moving parts in three basic areas require safeguarding. Dangerous moving parts in three basic areas require safeguarding. The basic steps to prevent accidents are- Eliminate the hazard from the machine method material structure etc.

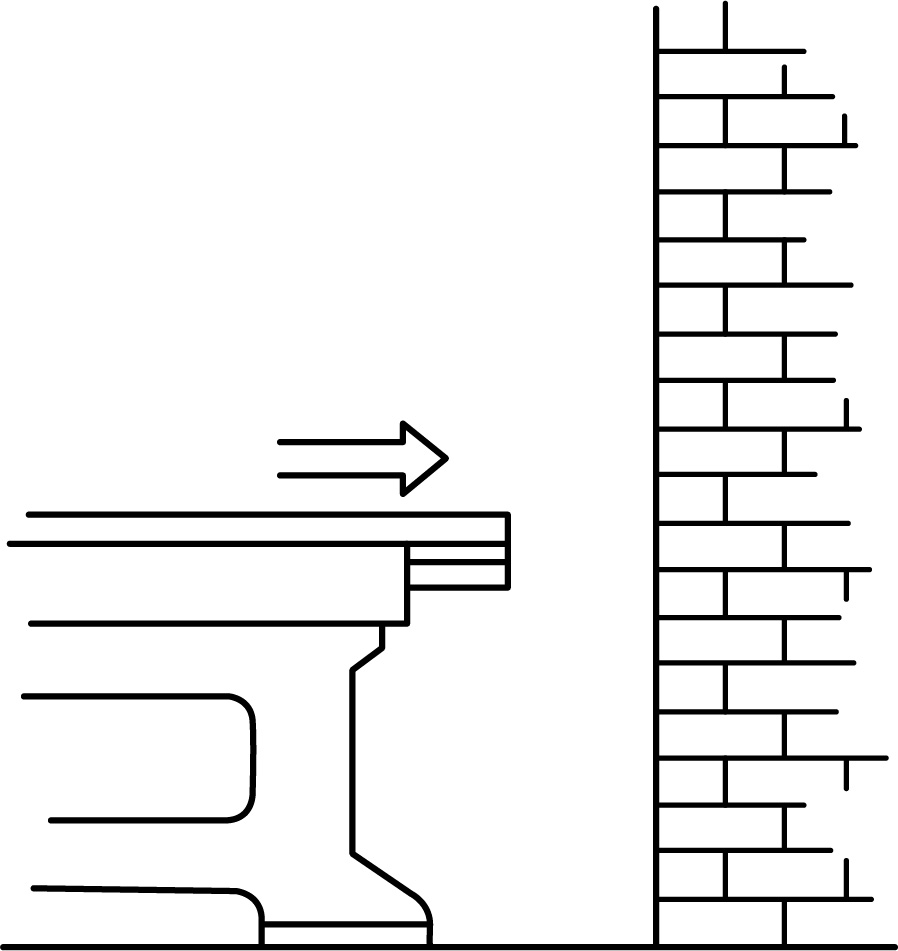

What are the four basic principles of machine safeguarding. That point where work is performed on the material such as cutting shaping boring or forming of. Dangerous moving parts require safeguarding because these three areas of the machine are most likely to cause injuries.

Methods of Machine Safeguarding. All machines consist of three fundamental areas. Prevent hazardous machine motion during human.

That point where work is performed on the material such as cutting shaping boring or forming of. Aside from guards another common safeguarding method. Dangerous moving parts that need safeguarding are located in the three basic areas described below.

That point where work is performed on the material such as cutting shaping boring or forming of. The point of operation is the point where. That point where work is performed on the material such as cutting shaping boring or forming of.

Basic Requirement For Machine Guarding

Chapter 1 Basics Of Machine Safeguarding

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Machine Guarding Environmental Health Safety

Osha Requirements Machine Guarding Grainger Knowhow

Machine Guards Eliminate Hazards For Employees Article The United States Army

Chapter 1 Basics Of Machine Safeguarding

Osha Requirements Machine Guarding Grainger Knowhow

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Osha Requirements Machine Guarding Grainger Knowhow

Basics Of Machine Guarding Ppt Download

Finding The Right Machine Safety Partner For Your Company Occupational Health Safety

1 Objectives Objectives Course No 204 Machinery And Machine Guarding Standards Course Identify Basic Machinery Terms Identify Common Machines Found Within Ppt Download

Osha 10 Hour Machine Guarding Presentation 4

Machine Guarding For Workplace Safety Safesite

Mining And Petroleum Training Service Basics Of Equipment Guarding Presented By David Spann Presentation Developed By Rene Azzara Ppt Download